For the mounting board I've used 1/2" foam core board. It works fine for small pieces; the largest one in this group is 41" long x 4" wide. I measured and cut the mounting board using a fresh blade in the utility knife. A cutting mat is quite helpful for this process as is a metal yard stick.

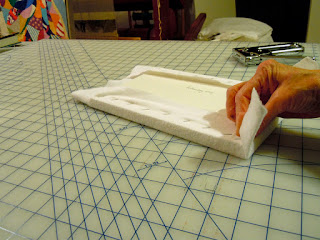

Next, I stretched a layer of cotton flannel (prewashed/dried) over the board using 3/8" staples. I clipped the ends and trimmed excess cloth away.

The mounting fabric in this instance is a natural color of cotton twill canvas. It was also washed, dried and this fabric was steam pressed (no need to press the flannel since it smooths out when stretching and stapling it.)

Excess fabric was clipped out of the corners, then the edges folded over and stapled at the back. This step is a bit tricky--you want to pull the corners as tightly and smoothly as possible. Staple and then you're ready to stitch on the tapestry.

The tapestry is laid onto the mounting board and pinned in place temporarily with t-pins. The mounting boards are about 1/4" to 1/2" larger than the tapestry so there's a small margin showing around the edges of the weavings.

Before mounting, the ends of the warps are dealt with... for small pieces that aren't four-selvedge woven (which leaves no loose warps to deal with), I usually use a half-Damascus edge that Peter Collingwood describes in his book, The Techniques of Rug Weaving. It's shown on pages 484-486. The process is done with the face of the tapestry down and it makes the warp ends lay against the back/body of the tapestry. Then I whip-stitch the warp ends down, four to six grouped together. And wefts that are near the edges are also tucked to the back with a whip stitch.

Using a curved needle, the tapestry is stitched to the mounting fabric, moving around the edges. A color of sewing thread that will blend with the edge colors as well as possible is what was used, although I changed color of stitching thread if the value contrast of the weft at the edges was great. On the pieces with the warp showing at the edge, the stitching color was changed to the warp color (usually natural color).

The curved needle will slip into the mounting fabric, travel up about 1/4" and then come out between the first and second warp. Pull the needle out, bury the sewing thread between wefts, then put the needle across to the mounting fabric again where you'll take another stitch under the fabric to the next point of attachment to the tapestry.

|

| This is a curved needle... although looks straight here. |

For hanging, there are several solutions... you can use an adhesive hanging system, sawtooth hangers, or velcro. I was able to locate enough push pin sawtooth hangers to use for the tapestry diary pieces at the local hardware. This is an easy method to use and should stay in place just fine.

The mounting board may also be put into a shadowbox-like frame. That's what I'm going to do with several of the smallest tapestries--frames will have to be built to size by a local craftsman in this case since I haven't been able to find shadowbox frames as small as I need.

And... here are the framed pieces... Jeff just delivered the frames a short while ago. They're exactly what I wanted for these pieces.